Engineering application

01

Design

Tailor made with process

02

Manufacture

Comprehensive qualification and meticulous construction

03

Install

Experienced, conscientious and responsible

04

Debugging

Validation of Sterility after startup

05

Train

On site training

06

After-sale service

One year warranty and lifelong service

Application area

Laboratory, pilot and industrial scale-up

Tianhui company can design Biotechnology Laboratory for customers, provide complete sets of equipment for Biotechnology Laboratory

Light industrial food fermentation

The patent product of Tianhui company is air lift inner loop fermentor (AIF). At present, the maximum volume of single tank is 500m3, which is used for...

The patented technology of Tianhui company can double the capacity of the reactor, meet the requirements of high efficiency, energy saving, good...

With the attention of human beings to the safety of agricultural products and ecological environment, microbial pesticides will have a...

Petroleum and petrochemical industry

As a deep dewaxing process to produce special oil products, microbial fermentation dewaxing has its unique side in the development of microbial...

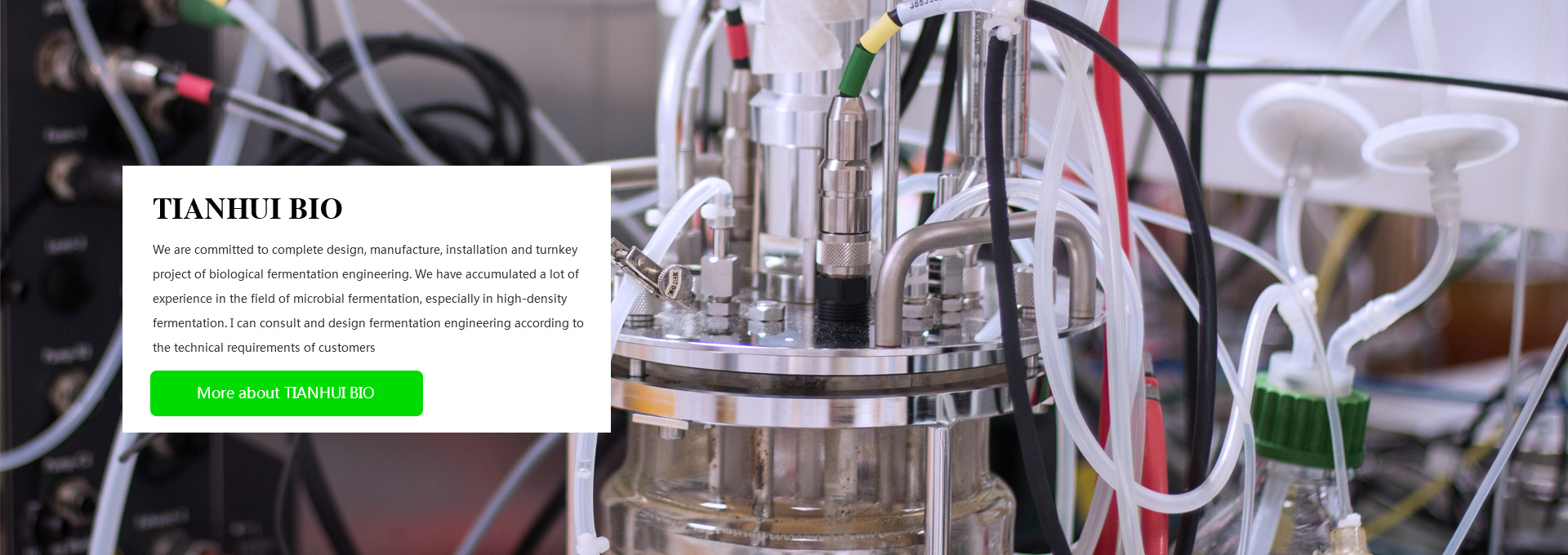

Company profile

Committed to the design, manufacture, installation and turnkey project of complete equipment for biological fermentation process, accumulated a lot of experience in the field of microbial fermentation, especially in high-density fermentation. We can consult and design fermentation engineering according to customers' technical requirements

Founded in 2007

Factory area

workshop area

Registered capital

News

New Year's message from the General Manager of Nanjing Tianhui Company

The law returns to spring, and the new era begins. On this beautiful occasion of bidding farewell to the old and welcoming the new, on behalf of Nanjing Tianhui Biotechnology Equipment Co., Ltd., we would like to extend our sincere gratitude to the hardworking and enterprising frontline workers, the dedicated internal staff who are closely connected to Tianhui, the energetic and innovative technical personnel, and the new ones who care about and support the company's development ..

2019-04-17

On the morning of October 18, 2010, the "Fengyuan Biochemical Technology Innovation and System Construction Mobilization Conference" was grandly held in the auditorium of Fengyuan Biochemical Company. Professor Hong Housheng and others were appointed as guest experts at Fengyuan Biochemical and awarded certificates. Cao Longcan, Deputy Mayor of Bengbu Municipal Government, Gong Kailin, Deputy Director of the Municipal Science and Technology Bureau, and other leaders were invited to attend and give speeches. Xia Linghe, General Manager of the company, made an important speech, thanking Hong Housheng and other attending university experts and professor representatives.

2019-04-17

The liquid vinegar project undertaken by Nanjing Tianhui Biotechnology Equipment Co., Ltd. for Weifang Jiahe Biotechnology Brewing Co., Ltd. has recently completed equipment delivery and pipeline installation. Through joint efforts of both parties, the agreed contractual requirements have been achieved.

2019-04-17

The fermentation system project of Zhejiang Weilu Environmental Technology Co., Ltd. undertaken by Nanjing Tianhui Biotechnology Equipment Co., Ltd. completed equipment supply and on-site pipeline installation work in June 2015. Through joint efforts of both parties, it met the requirements of the contract signed by both parties. All equipment completed pressure and leakage testing and linkage debugging, meeting the requirements of the contract signed, and passed the acceptance on July 14, 2015.

2019-04-17

中文

中文  英文

英文